AUTOTRANS SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to AUTOTRANS SYSTEMS

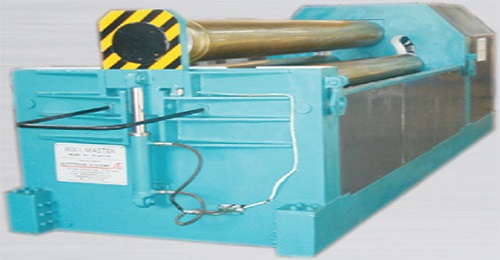

Roll Planetary Axis Plate Bending Machines

The three roll planatory axis is a three roll machine having pre pinching/pre bending facility within the machine. The plate can be inserted from one side and is clamped between top roll and one of the pressure roll for a firm grip and the another pressure roll advances further to form desired radious of shell. The same procedure is repeated but on another side of plate to form desired radiouse. After having done pre pinchind the plate is formed in to circular shape by rolling and further pressing of pressure rolls and by forward and reverse movement of rotation by rolls. Usually a shell is formed in multiple passes of rolling by forward and reverse movement of rolls in rotary motion. It is also possible to form shell in a single pass provided the pressure roll position is well known for particular size of shell rolling by regular practice and experience. The PLC based machine is most suitable for repetitive type of jobs and shapes required regularly Other shapes can also be forme in this machine in single pass like square, polycentric,elliptical or open rolling.

Standard Featues

All 3 rolls are positively driven by in line mounted planetary gear box and hydraulic motor Roll parallelism maintained by solid linkage mechanism

Digital display for roll position for ease of rolling and for fast rolling of repetitive type components

Spherical roller bearings are used as standard in all our models

Heavy duty reinforced steel frames duly stress relieved and epoxy painted after sand blasting

Optional Features

Electronic proportional balancing using hydraulic system specially developed for plate bending a machine

Induction Hardened rolls for 52-55 RC hardness

Conical bending device

Provision for section rolling

Section bending dies

Overhead support

Lateral support

Auto plate squaring reference stopper

Tilt able top roll

Automatic roll speed compensation

Advantages

More suitable for small engineering work shop where bending requirement in small quantities and in different sizes as per job requirement

Less costly compared to 4 roll machine, hence low initial investment

Both leading and trailing edge can be pre bend in single pass. No need to remove and reinsert material

Small engineering workshop willing to invest less still automate rolling

Open type rolling requiring mass production quantity

Can use as a straightening machine for pre formed material for reuse

Can use where different operations like pre bending, rolling, material straightening ,Conical rolling, section rolling need to be carried out in single machine.

Application

Railway: water tank, tankar, coach bogie wall profile bending/rolling Automobile: silencers, fuel tanks, mufflers',

Offshore: drill rings

Storage: silos,tanks,

General engineering: Pressure vessal,boiler, tanks, piping, filter body

th moving: Excavator bucket, road roller drum, mobile compactors

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.